Alfa's first CA(R)Tastrophe

Part 3: The hardware Alfacorse went into combat with: March 89CE and its V8

Authors

- Henri Greuter & Aldo Canzian

Date

- May 17, 2022

Related articles

- March-Alfa Romeo 89CE - Alfa's first CA(R)Tastrophe, by Henri Greuter/Aldo Canzian

- Introduction

- Part 1: About what happened late 1988 and early 1989, as printed in the British press

- Part 2: From late January '89 to the first race

- Part 4: Alfa's 1989 CART season

- Part 5: Evaluations of the past year, closing the book and into the future

- Appendix 1: The 1989 race results

- Appendix 2: The search for the identities of the two Morales Racing March 88Cs

- March-Alfa Romeo 90CA - Fiasco Italo-Brittanico, by Henri Greuter

- March-Porsche 90P - The last oddball at the Indianapolis Motor Speedway, by Henri Greuter

Who?Roberto Guerrero What?March-Alfa Romeo 89CE Where?Balocco When?March 1989 |

|

Why?

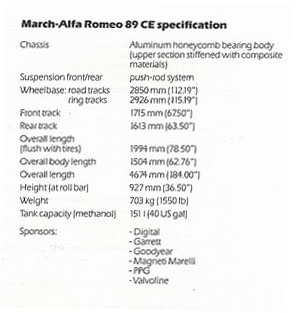

Alfa Romeo made its CART debut in the weekend of June 16th, during the race held at Detroit. A press kit was released during that weekend. It contained information about the 89CE chassis.

The design of the car was credited to Maurice Philippe with the aid of state-of-the-art technologies, among which CAD.

According to the regulations, the monocoque was a composite aluminium alloy honeycomb base with a carbon composite top section. The primary aim of the design was to obtain maximum stiffness of both the actual monocoque as well as the monocoque/engine construction. The monocoque had new design features onto the rear flameproof bulkhead, manufactered from aluminium and carbon as well. This in order to improve the torsion and bending stiffness. For the very same reasons the top mountings of the suspension units, the top of the final drive case and the aluminium fixture that linked the cylinder banks were also redesigned.

The car used a newly designed transmission case in order to mate with the Alfa V8. It was strengthened for a stiffer connection to the engine and allowing optimal low positioning of the turbocharger. The case also featured the mounting points for the top parts of the rear suspension so that it became possible to change the gear ratios without removing parts of the rear suspension.

About that rear suspension: It was pushrod-operated with the pushrods working in the same geometrical plane as the rockers to minimise friction losses. The pushrods operated off the bottom wishbone, this to reduce deflections in the casting and bump steer. The double wishbones had magnesium uprights.

The front suspension featured a novelty for March's Indycars. Instead of the long-time pullrod system, the 89CE's front suspension was pushrod-operated. The pushrods operated suspension units which were coaxial helical springs with telescopic shock absorbers mounted inside the monocoque.

Different aerodynamically shaped wishbones for either road tracks or speedways were available to adjust the wheelbase as preferred.

The car used a minimum number of bodywork parts in order to reduce airflow disturbances caused by joints. Sidepod tops and engine cover were a single part, the sidepod tops had the cooling air outlet ducts moulded in.

The underfloor was also a one-piece construction.

Each sidepod contained water radiators and oil/water heat exchangers. They were fed by water pumps at the front of each cylinder bank. There was a single oil scavenge pump with two outlets. The left sidepod contained the engine management system and the so called 'black box'.

The technical specifications of the car as listed in the press kit.

Roberto Guererro posing with one of the two 89CE's. (photo copyright Alfacorse PR)

Another shot of the 89CE as provided with the June '89 Alfacorse press kit. (photo copyright Alfacorse PR)

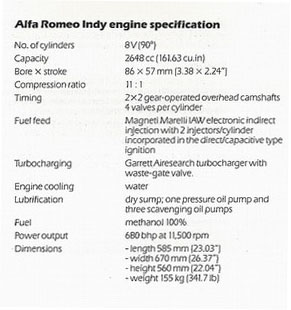

Information about the engine had been released at an earlier moment: during Alfa Romeo's press conference held in Italy.

Using the information supplied on that occasion and printed in magazine articles about this press conference as well as the information as released in the 'Detroit press kit' we can tell the following about the Alfa V8.

In October 1988, Alfa Romeo had started the design of a compact turbocharged V8 CART engine with which to start off their CART project. This was to enable the chassis to have the largest ground-effect diffuser possible as well as allowing the airflow to the rear wing to be as clean as possible. It took a reported four months to design the engine. Length, width and height were 585, 670 and 560mm, weight was quoted as 155kg. Bore and stroke were 86x57mm, giving a capacity of 2648cc. The power output was rated at 680hp at 11500rpm.

At first sight, this was lower than the claimed 710hp for the 1986 Ferrari 034 engine. This was a result of the reduction in maximum allowable turbo boost from 48 to 45 inch mercury introduced in 1988.

Although the Alfa V8 was inspired by the Ferrari 034 engine, the Alfa engine had a conventional design of exhausts on the outside and inlet plenum within the V. The Ferrari 034 had been rather unique because of having the exhausts within the V like they had done with the turbocharged V6 F1 engines used from 1981 to 1984. In post-war Indycar history the very same layout had been used in only a single engine: the turbocharged version of the Ford Quadcam V8 that was used between 1968 and 1978.

The engine design team was led by Claudio Lombardi and consisted of Giovanni Roffina, Luciano Caruso and Giuseppe D’Agostino. Special attention was given to the fact that the engine had to run on methanol and all the consequences related to the use of this fuel. During October 1988, the engine was still on the drawing board. In February 1989, however, it was running on the test bench. The engine made extensive use of small magnesium parts. Another weight-saving measure was the use of silicon aluminium cylinder liners within the cylinder block instead of more standard ductile iron liners. This alone saved 10kg. But some of the effects of all this weight reduction was lost instantly because of the use of a harmonic balancer mounted on the rear of the crankshaft and then connected with flywheel and clutch. The balancer reduced the vibrations running along the crankshaft but its use made it necessary to enlarge the bellhousing. None of the other CART quadcam V8 engines used such a crankshaft balancer.

The engine also received a fully electronic management system made by Magneti Marelli, complete with an electronically controlled wastegate for the turbocharger, which was made by Garrett.

Technical specifications as listed in the Alfacorse press kit, released on June 16, 1989.

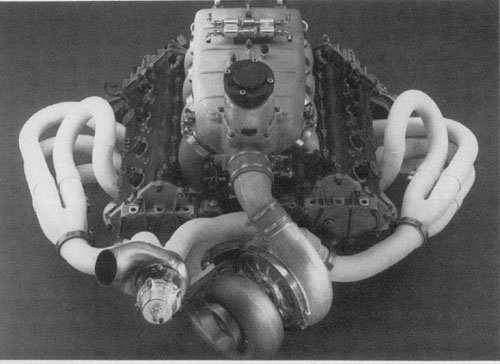

Picture of the Alfa Romeo V8 as released in the June '89 press kit. (photo copyright Alfacorse PR)

With hindsight...

The information released to the press about the 89CE has been proven to be too optimistic in several respects.

Johnny Capels informed us that it was his crew who completed the two 89CE cars, and they discovered that the cars had a complete miscalculation on the make-up of the tub and the torsional rigidity it should have had. There was, however, no more opportunity to correct this and the cars eventually went to the US as they were and were raced as such.

Then, to re-quote a comment we got from Johnny Capels a second time:

“With our help in the March shop we did have two new '89 March models ready for Indy but the progress of the engines was not to Alfa's satisfaction. The March chassis was conceived very quickly and basically was not anything new.”

Which supports a lot of claims about the strong 88C heritage of the 89CE, with practically no input from the 89P project into the 'in-house opponents' at March.

And indeed, when looking at the PR pictures of the car that were released, if the front suspension of the car is not visible you will have to look very, very closely to know whether you are dealing with an 89CE or an 88C.

Nevertheless, this was the car that arrived in the US to defend Alfa Romeo's honour in its first season in the CART series.